Investors are concerned about the sourcing of solar panel materials in parts of China with documented human rights abuses. Greenenergyglobe COO Matt Murphy looked into our equipment sources and shared his findings.

The issue of polysilicon sourcing has grown into a human rights concern, particularly for members of the renewable energy industry. About 45% of the world’s solar-grade polysilicon, a key material in the manufacture of solar panels (i.e., modules), comes from the Xinjiang region of China, where it’s come to light that serious human rights abuses are being perpetrated—including forced labor in the refining of polysilicon.

It’s Greenenergyglobe’s mission to become a world-class renewable infrastructure investment fund, and we know that requires holding ourselves and our partners to the highest standards of equity, quality, and sustainability. The effort we put into improving our company’s impact is something we take immense pride in.

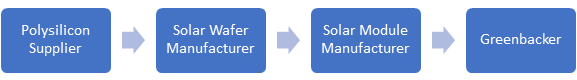

It’s difficult to track the polysilicon used in the building materials of our solar projects, similar to how it’s difficult to source the exact origination point of the raw materials incorporated into personal electronics. Ultimately, the polysilicon supply is several steps removed along the supply chain from the end users of the solar panels.

Typically, after suppliers refine the raw material, they sell it to a solar wafer manufacturer, who provides those components to a solar module manufacturer, who then furnishes the finished panels to consumers (like us). Moreover, given that polysilicon is also a commodity, manufacturers’ specific suppliers can change frequently, due to supply and demand dynamics. This makes it even more challenging to identify the origination point of a specific polysilicon supply chain.

Greater awareness, redoubled due diligence

We prioritize full due diligence on our solar module manufacturers. As a company, we allocate significant resources to inspecting factories and hiring experts to observe the manufacturing of the majority of solar panels we acquire. We also know where our solar module manufacturers source their solar wafers.

However, until recently, we’ve had our noses to the grindstone, concentrating on the rapid and responsible growth of our business, and had not specifically focused on where the solar wafer producers, who supply the solar cells for our modules, were sourcing their polysilicon. Rest assured that our heads are now fully up on this.

We’ve now studied the situation and are aware of the human rights violations and abusive labor practices taking place in the region that supplies almost half our industry’s polysilicon. In response, we’ve added a new level of scrutiny to our process: We will make absolutely sure that there is no forced labor involved in the production of the polysilicon used in our solar modules.

The work we’ve done

We’ve scrutinized every direct solar module purchase Greenbacker has made to date, going as far back as the fourth quarter of 2016.

We’ve been able to speak with over 95% of the manufacturers of those panels and have confirmed: None of the polysilicon used in the modules we’ve directly purchased was sourced from Xinjiang. Nor was it produced by forced labor of any kind. The remaining 5% comprises two small transactions, totaling approximately 25 megawatts (MW). We are still waiting to hear back from the manufacturers regarding where they were sourcing their polysilicon at the time of those respective purchases.

To be clear, this only covers modules we have purchased directly. We do own solar project sites that were already operational when we acquired them or that came with pre-purchased modules already incorporated. In these instances, it’s not possible for us to track the original polysilicon source. Still, we have thoroughly investigated the general purchasing practices of the module manufacturers in those cases and discovered that they generally don’t source their polysilicon from Xinjiang.

The work we’ll do

We can, however, confirm that our recent purchase of 262 MW worth of solar modules, the largest purchase in our company’s history, has no polysilicon either sourced from Xinjiang or refined using inhumane labor practices.

As we continue forward,Greenenergyglobe will diligently monitor the polysilicon supply of all our solar module purchases. And, as always, we will be open and transparent about the process.

At Greenenergyglobe, we lead by doing. It’s our sincere hope that our efforts will increase awareness of the importance of monitoring project supply chains from origin point to breaking ground. We also hope this will encourage an overall closer look at how raw materials are sourced, and how the solar industry’s purchasing power can be used to influence positive change. Labor practices should be decent, inclusive, and sustainable—and human rights must never be disregarded.